Ruby needle

The needle is made of ruby, which is suitable for high-precision dispensing and micro dispensing. It can be processed and customized according to the needs of customers, φ 0.05~φ 0.5 Machinable.

This product has high fluidity and no static electricity. The front end of the needle is polished, which can prevent the dispensing deviation and material creeping due to the difference between the front end of the dispensing needle and the surface tension of the dispensing material.

| Standard dimension table | ||||

| Product name | Model | Front end size | Material | |

| Inner diameter (mm | Outer diameter (middle) mm | |||

| RUBY NOZZLE | SPN-R-O5 | 0.05 | 0.15 | sUS+RUBY |

| SPN-R-07 | 0.07 | 0.17 | sUS+RUBY | |

| SPN-R-10 | 0.1 | 0.2 | sUS+RUBY | |

| SPN-R-15 | 0.15 | 0.25 | sUS+RUBY | |

| SPN-R-20 | 0.2 | 0.3 | sUS+RUBY | |

| SPN-R-25 | 0.25 | 0.35 | sUS+RUBY | |

| SPN-R-30 | 0.3 | 0.4 | sUS+RUBY | |

| SPN-R-35 | 0.35 | 0.45 | sUS+RUBY | |

| SPN-R-40 | 0.4 | 0.5 | sUS+RUBY | |

| SPN-R-45 | 0.45 | 0.55 | suS+RUBY | |

| SPN-R-50 | 0.5 | 0.6 | sUS+RUBY | |

special shape customized products, Shiqiao unique needle

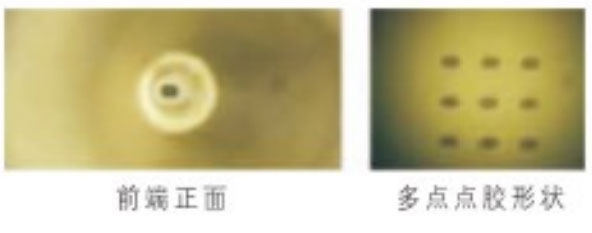

elliptical needle half conductor substrate package

- corresponding to multi-point range dispensing needle

- change the front end of the needle into an oval shape. Combined with the size of the chip, reduce the dispensing times from two to one, so as to improve the production efficiency.

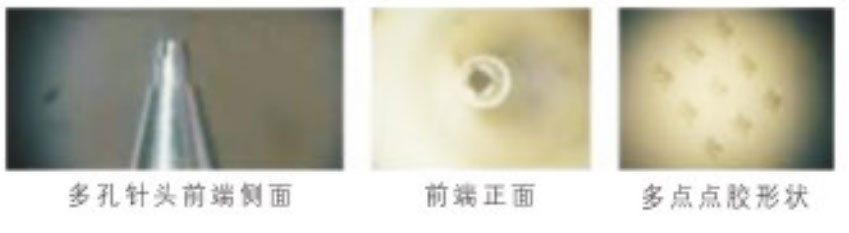

porous needle semiconductor substrate package

- corresponding to multi-point range dispensing needle

- in recent years, the mainstream painting dispensing mode reduces 4 points of glue to 1 point, effectively reducing the production cost.

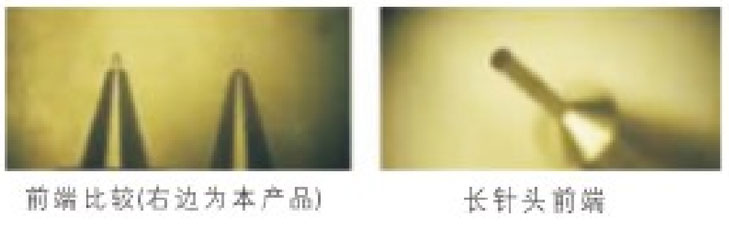

long needle LED (phosphor), CMOS

- low viscosity material / low pressure dispensing needle

- is applied to low viscosity materials and has good performance. Using the long needle with long needle resistance, even the low viscosity material which is very difficult to control, and the low-pressure dispensing control with pressure below 0.1 MPa also has good results.

fine needle crystal oscillator

- corresponding to dispensing needle in narrow space

- it is applicable to the needle with narrow dispensing range. In order to avoid collision with the device during dispensing, the inner diameter of the needle is not changed and the outer diameter is reduced. Generally, the wall thickness of the front end of the needle is 50 & mu; m. The minimum fine needle can reach 25μ m. It can effectively solve the problem of difficult dispensing in narrow space.

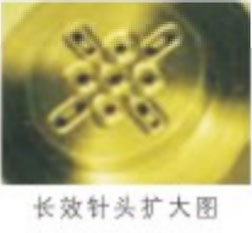

long life needle chip package

- atomic seal needle

- in the past, it was necessary to move back and forth to take glue and replenish glue from the material tray. Now the glue can be directly supplied through the needle tube, which saves the time of taking glue and replenishing glue from the needle, and the production capacity is significantly improved.

- body needle all dispensing processes

- High fluidity dispensing needle

- The needle closest to the original principle and function of the precision needle. Generally, the screw part of the split needle is easy to retain phosphor or other filling materials, which will lead to the change of material properties. The integrated needle avoids the problem of changing material characteristics, makes it easier to locate when replacing the needle, and improves the cleaning performance.

multi needle

prevent the needle tube from falling off and liquid leakage treatment

the glue dispensing needle tube and the needle base are fixed by riveting after being pressed in instead of using adhesive to prevent the needle tube from falling off and liquid leakage.

prevent needle tube from sinking

process with original technology to effectively prevent needle tube from sinking.

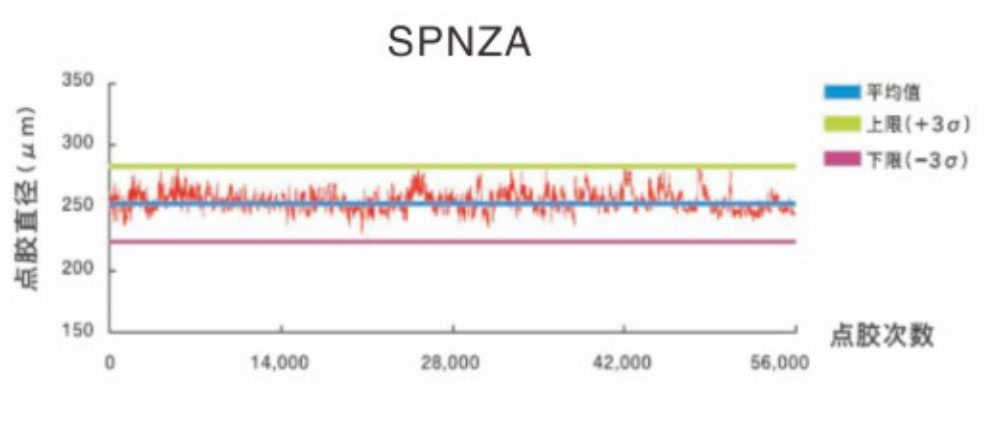

stabilization of dispensing amount: for the internal polishing of needle tube

, the needle

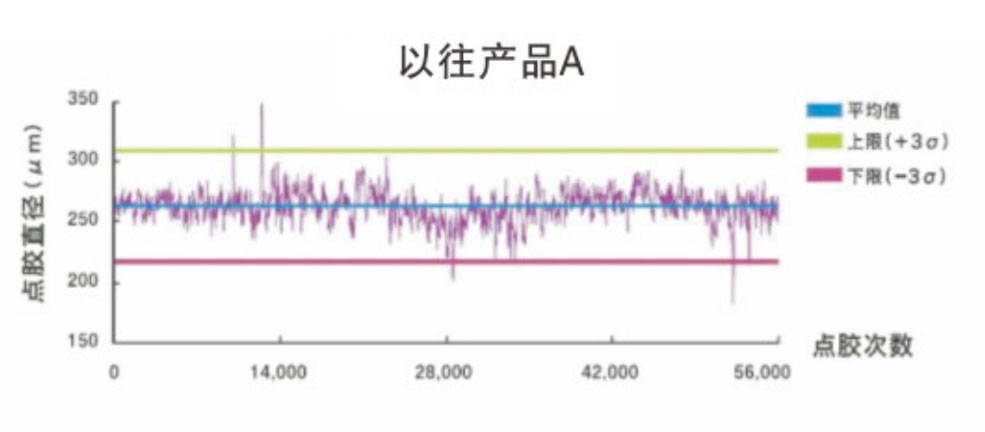

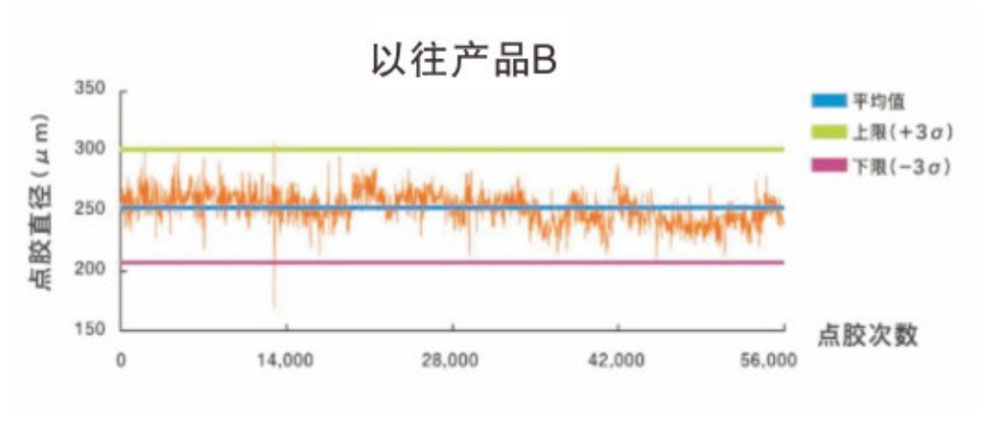

with inner diameter polishing can be customizeddispensing stability (Soil & sigma;)

| average dispensing diameter | 3σ | |

| SPNZA | 255 um | 26.1 um |

| previous products a | 263 um | 42.5 um |

| previous products B | 251 um | 43.3 um |

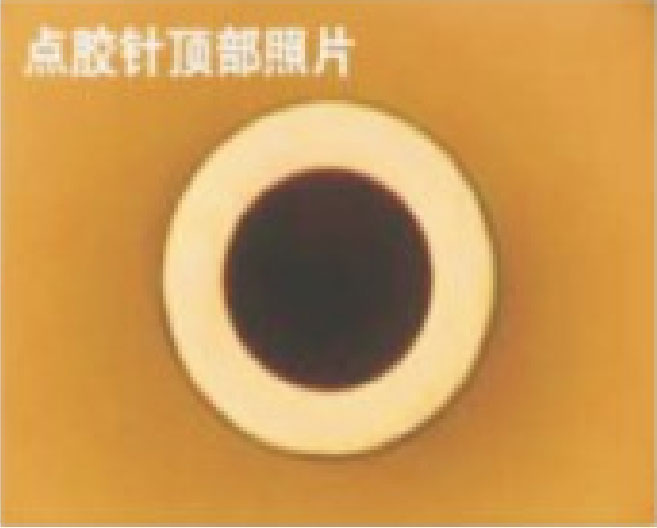

front end polishing

the front end is polished

no glue creeping after 15000 dispensing

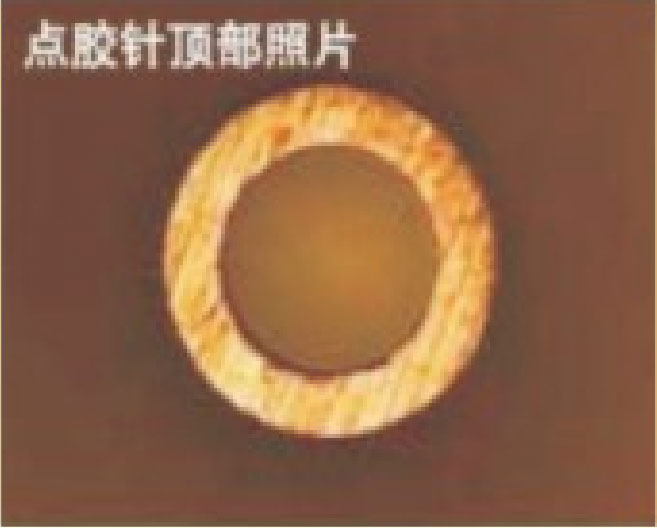

no polishing at the front end

the front end is polished, and no glue creeping phenomenon is found after 15000 glue dispensing.

the front end is not polished, and glue creeping phenomenon will occur after 5000 glue dispensing.

internal machining shape and material blockage

-

Shiqiao products

-

previous product a

-

previous product B

there is no segment difference design inside, and the material is not easy to be blocked